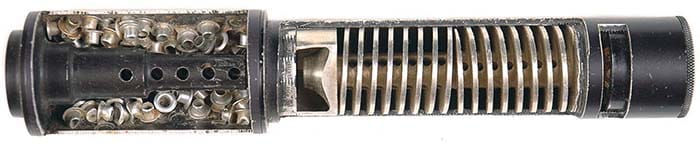

An “old school” MAC 2-stage suppressor cut-away. The first stage used shoe string eyelets for heat absorption. The second stage had a conical baffle to trap gases and absorb heat and direct the gases rearward, next were right and left spiral diffusers to slow down the escaping gases. At the front of the tube was an encapsulator with neoprene wipes.

By Frank Iannamico

In recent years the suppressor business has (silently) boomed. The reason for the sudden demand for suppressors (also known as silencers) is unclear; they have been available for many years from a number of manufacturers. Many of the older companies that manufactured suppressors “back in the day” are gone, however an ever growing number of new firms have sprung up to meet the current demand. Many large retailers, wholesalers and local dealers have now added suppressors to their product line. Suppressors have become such a mainstream item, many firearm manufacturers now offer models with factory threaded barrels to mount them.

The initial credit for producing suppressors for the civilian market can be traced back to the same company that made submachine guns available for the commercial market, the Military Armament Corporation. The suppressors sold by MAC were originally a product of Mitch WerBell III’s SIONICS Company, which eventually became the Military Armament Corporation. Although MAC originally focused their attention on government and military customers, a large number of their suppressors and submachine guns were made available to the public after being sold at their bankruptcy auction in 1976. Companies that followed MAC, like RPB and SWD, sold basically the same products as the Military Armament Corporation, except they concentrated on civilian sales, a market that was beginning to grow rapidly.

The original sound suppressors designed and sold by the Military Armament Corporation were quite large, when compared to most of the suppressors available today. However, in their day the SIONICS suppressors were considered state of the art. There were several different suppressor designs manufactured. The first type was a two-stage unit for the 9mm and .45 caliber Model 10 submachine gun, that consisted of a rear tube that served as the gas expansion chamber, and was filled with aluminum eyelets or wire mesh to provide maximum heat absorption. The front tube had a conical baffle to trap gases and absorb heat and direct the gases rearward, delaying movement into the next component. After the gases passed through the baffle, they encountered a spiral diffuser that absorbed additional heat, and caused the gas to swirl around its left-hand twist design. The next component was another spiral baffle but with a right-hand twist, that also absorbed heat, and slowed down the escaping gases, by reversing their direction. At the end of the front tube was an encapsulator, which was threaded onto the end of the tube. Inside the encapsulator were two neoprene wiper discs. The neoprene wiper discs provided a gas seal as the bullet passed through them further delaying the exit of the propellant’s gas to the atmosphere. The service life of the wipes was relatively short, but replacement wipes were available from the factory. Encapsulators on early production models had a snap ring that allowed for easy wipe replacement by the owner. Later versions were crimped together making replacement more difficult. About the same time as the encapsulator “upgrade” MAC/ SIONICS began to sell replacement encapsulator assemblies with new wipes in them. The M11/.380 caliber suppressor was the same basic two-stage design as the Model 10 units, but the expansion tube and the front tube were similar in their outside diameter.

A

B

C

D

Many problems were encountered when customers attempted to take apart their MAC suppressors to service them. During initial assembly, the factory took great care to ensure that all of the internal parts were in perfect alignment. When an inexperienced individual would attempt to assemble a suppressor, bullets would often strike any misaligned components, causing permanent damage to the suppressor and sometimes to the customer. To discourage suppressor disassembly by customers, the company began to use a thread locking compound on the threads of the end caps. This made the suppressors extremely difficult to disassemble for servicing. This also increased company business when customers had to return their suppressors for servicing. Another common problem encountered with the original MAC suppressor designs was the coarse threads used to attach them to the MAC submachine guns, which caused the suppressors to loosen, during full-auto firing often resulting in damage to the unit.

Until recently, many suppressor manufacturers designed their products so they could not be easily disassembled. The purpose was to prevent the end user from taking them apart for cleaning, primarily so that the baffles would not be accidently misaligned, damaging the suppressor. However, due to customer demand, many companies began to offer new suppressors that could be easily disassembled by their end users. New improved designs made it easier to keep the baffle stacks properly aligned and less likely to be assembled incorrectly. Original manufacturers as well as specialty firms began to offer a service to open up older sealed suppressors and convert them into customer serviceable units. The process of opening up a sealed suppressor coined a new term “jail break”. Customer-serviceable suppressors are not without their drawbacks. If not routinely disassembled at factory recommended intervals, they can become hard or impossible to take apart. In many cases owners resort to desperate measures in attempting to disassemble their suppressors, this often results in damage to the tube. Replacing a serial numbered suppressor tube would require a second $200.00 Federal transfer tax.

Replacement Baffles

A question that occasionally arises is “why can’t I own any suppressor baffles or parts?” Being able to simply replace baffles would be easier than trying to clean an extremely dirty suppressor.

Back in the 1980s there were several companies selling suppressor tubes; and a second company, often affiliated with the first one, but operating under a different name, offering internal suppressor parts. Separately, there were no restrictions on tubes or baffles (but it was illegal to possess them together). This soon became a problem as there were beginning to be a substantial amount of unregistered suppressors out there being assembled by individuals. Many of the suppressors were being found in the possession of criminals. To stem the flow of illegal suppressors, action was taken in May 1986. The Firearm Owners’ Protection Act amended the NFA definition of “silencer” by adding combinations of parts for silencers and any part intended for use in the assembly or fabrication of a silencer, except by class II manufacturers. NOTE: Possession of an unregistered suppressor is a serious felony. The $200.00 registration/transfer tax will seem cheap, compared to the legal fees you will face when you’re caught, not to mention a felony conviction, fine and a stay in federal prison.

Threaded Barrels

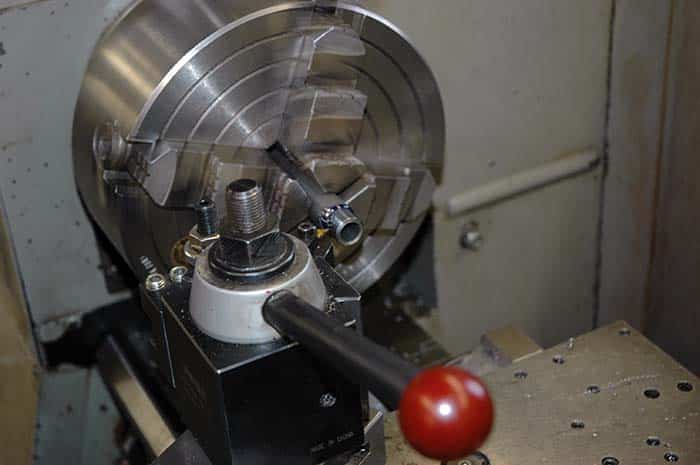

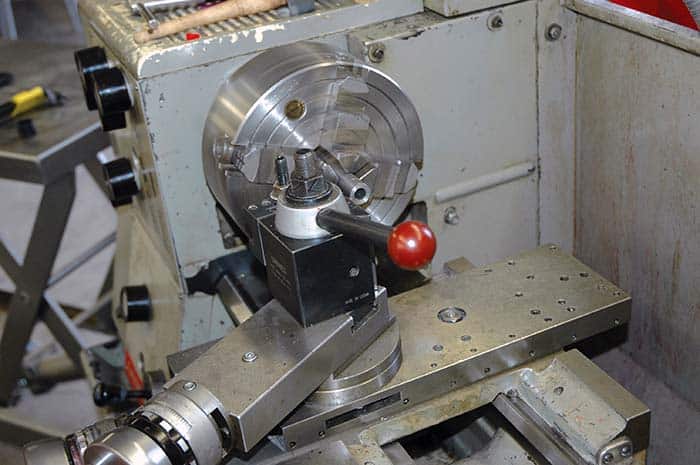

Another leading cause of suppressor baffle strikes is a firearm’s barrel that has been threaded incorrectly.

Although many manufacturers now offer factory threaded barrels, there are still many firearms with barrels that are not threaded and the owners would like to mount a suppressor on them. However threading a barrel is not as simple or easy as it may sound. It isn’t a matter of just running a threaded die over the muzzle to cut the threads. The reason is that the outside diameter of the barrel being threaded may or may not be concentric in relationship to the bore. In other words if not threaded correctly the centerline of the barrel’s bore may not be perfectly in line with the center of the suppressor. This misalignment will most likely cause the bullet attempting to pass through suppressor to strike the baffles inside damaging the suppressor or injury to the shooter.

There are a growing number of do it yourself (DYI) barrel threading tools on the internet market for home gunsmithing. These devices may be sufficient for attaching a muzzle brake or flash hider, but are not recommended for threading a barrel for the mounting of a suppressor. If the barrel’s outside diameter is not concentric to the bore you’re going to have a problem. You might be able to convince the manufacturer to repair it under warranty, but that will probably only happen once, and you’re going to need a new barrel, or have your existing barrel cut and rethreaded correctly, to prevent another baffle strike.

To correctly thread a barrel for mounting a suppressor, it should be done on a lathe by a gunsmith experienced in barrel threading.

| This article first appeared in Small Arms Review V20N3 (April 2016) |